Excitement About Welders In Leeds

These makers are best fit for welding solid core and flux products - welders in leeds. They can deal with mild steel, low carbon steel, alloy steel, and so on are more specialized than the others and provide a tidy and pure weld without splatter, stimulates, or fumes. These machines can manage stainless steel, brass, gold, magnesium, aluminum, copper, and nickel alloys. Source: Julian Carvajal/Flickr tend to be used to sign up with overlaps between things like sheets of steel. To do this, metal sheets are generally safeguarded utilizing a pair of electrodes by passing a current through them. Area welders have many excellent advantages over others like efficient power utilization, high manufacture rates, easy.

automation, and so on. They are also usually a lot less expensive than their options. Shielded metal arc welding, likewise referred to as stick welding, uses an electrical current flowing from a space in between metal and welding stick. In this type of welding, electrical current is used to develop an arc between the base material and the filler rod( also called an electrode rod).

bonded, then stick welding is the winner. MIG can be used to a broader choice of metals of varying thickness, while TIG welding produces the highest quality welds, especially when it comes to thin metals. "Source: Vitalij Sova/iStock It likewise depends on the metal you wish to bond. For instance, welding aluminum can be difficult as it is a fairly soft metal which can't deal with too much heat. Of these two methods, TIG welding is widely considered to be the go to strategy for best outcomes. Stainless steel welding, on the other hand, is different, as it's a much beefier metal when compared to aluminum. For this reason, it can take a lot more punishment before compromising its strength. MIG welding is normally thought about to be the finest method for the majority of steel applications. When it comes to thicker steel sheets, many bow down before the superiority of stick and flux welding. If the steel is moderate and stainless, TIG welding and MIG welding can be utilized with no real problem. As their job is to protect your precious yet fragile human hands from possibly severe burns, selecting a great quality pair is absolutely essential. However there is no one-size-fits-all when it concerns welding gloves. Elements like the type of welding you'll be utilizing them for and just how much mastery you're going to need are all considerations - welders in leeds. MIG welding, continue reading this for instance, tends to produce a great deal of sparks that need to be protected versus Home Page and tidied up afterward. Gloves likewise can be found in a range of materials too. For the majority of users, leather is the most favored kind as it is resilient, non-conductive, and is great at dissipating heat. Some typical examples include: This kind of leather uses unrivaled abrasion and tensile strength while staying soft and flexible. This is ideal for TIG weldingwhere you require the maximum quantity of dexterity possible. Horsehide is tough a long lasting, yet remain comfortable.

Welders In Leeds for Dummies

While less popular, as leather gloves go, it is likewise great for TIG welding. This type of leather is excellent for TIG, MIG, and stick welding, to name a few. Cow leather is among the most typical type of leather. It is really durable and comfortable andis normally preferred for stick and MIG welding. A soft and flexible leather, the flexibility of motion it provides makes it another terrific choice for TIG welding. Elkskin is another fantastic option for MIG welding due to the high quantity of heat it emits. If you are new to the world of welding, some methods are much simpler to pick up than others. MIG welding, for example, is commonly thought about to be the easiest to get and run with. It also produces spick-and-span welds compared to most other techniques. It is likewise great as it is typically pretty quick, a function enjoyed by newbies and masters alike. Other techniques also exist if your budget enables. You could think about obtaining something called a hybrid welder. This lets you attempt numerous techniques with one tool. While welding is of great utility in numerous industries around the world, it can be used for other things too. One example is in the world of art. If you ever watched the ageless traditional animated movie, The Iron Giant, Dean McCoppin did simply that. Source: ShyCityNXR/Flickr Tracing our steps back into genuine world, numerous artists are utilizing strategies pointed out above to produce stunning works of art. This chap uses old bike chains to produce terrific visually pleasing sculptures. You need to really take a look at his work on Instagram. Another great welding artist is David Madero. This chap creates spectacular artworks using plasma cutters and spot welding techniques.

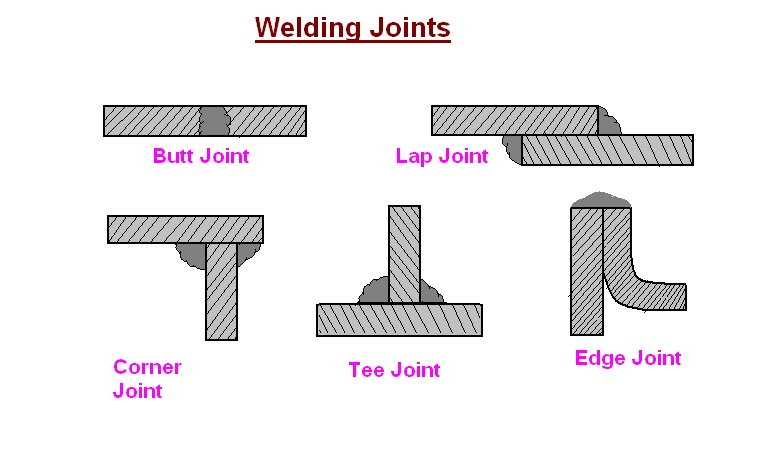

They are but two of the many artists worldwide creating interesting work utilizing the classic strategy of welding. Some products require the use of specific processes and strategies. A number are thought about',' a term not normally found in dictionaries but beneficial and detailed in engineering. The parts that are signed up with are referred to as a. The material added to assist form the join is called or. Consumables are typically chosen to be comparable in structure to the parent product, hence forming a homogenous weld, however there are occasions, such as when welding breakable cast irons, when a filler with an extremely different structure and, for that reason, homes isused. These welds are called important source heterogeneous. The completed bonded joint may be referred to as a.